About

DATAI

DATAI

DATAI supports your self-realization

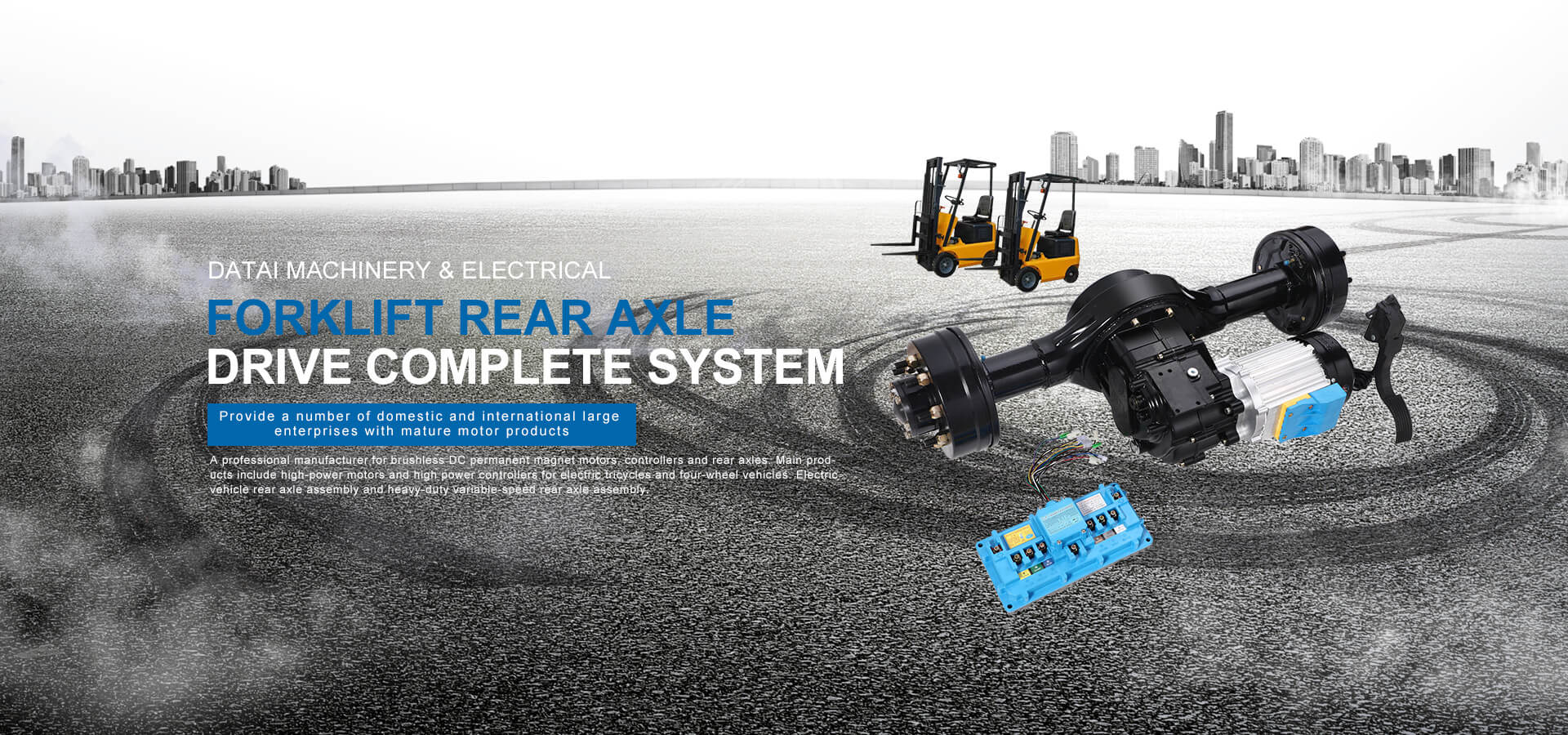

Zhejiang Datai New Energy Co.,Ltd. (formerly Taizhou Datai Machinery &Electrical Co., Ltd.) is an electromechanical manufacturer that was founded in 2008 and located in Taizhou City, Zhejiang Province. We are specialized in manufacturing the high-power six-phase permanent magnet synchronous motors and high-power controllers for electric tricycles and four-wheel vehicles, electric vehicle rear axle assembly and heavy-duty variable-speed rear axle assembly. Supported by the sophisticated technologies, we are able to provide a full range of specifications and models with high quality stability.

The company has powerful technological development teams and always focuses on product design, research and development. Following the business philosophy of "scientific and technological innovation and quality above all", we are continuously absorbing advanced technologies at home and abroad and accelerating product upgrading, and have obtained patents for our 12 products (including 5 invention patents).

The company has been included in the first batch of "Gazelle Enterprises" cultivation plan by Taizhou Municipal People's Government, and has been successively awarded the honorary titles of "Top 100 Enterprises in Huangyan District", "Municipal High-tech Enterprises", and "Small and Medium-sized Scientific and Technological Enterprise in Zhejiang Province". The company has obtained ISO9001:2015 Quality System Certification and CCC National Compulsory Product Certification.

MORE >

PRODUCTS

show

Products Show

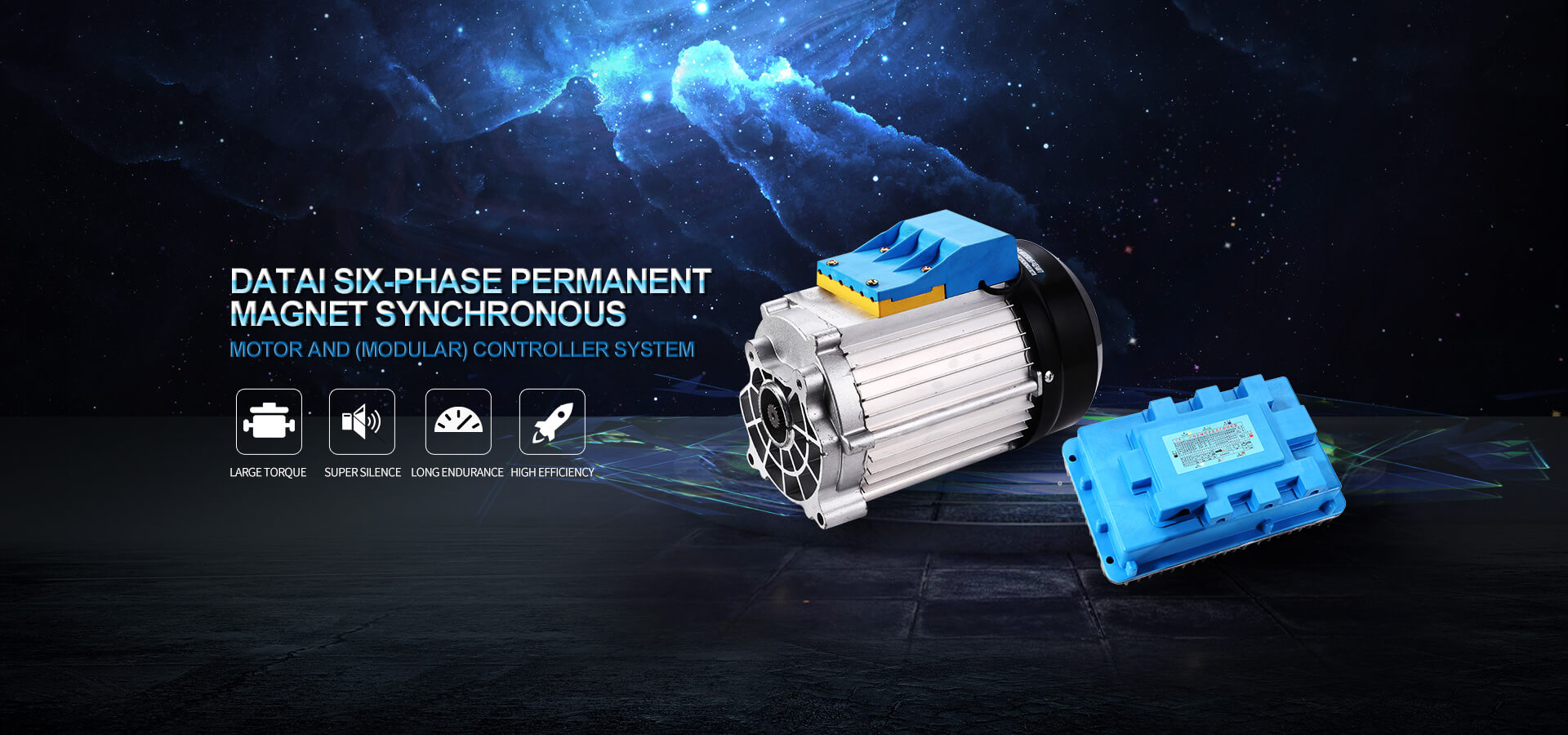

At present, the common bottlenecks in the drive system of high-power electric vehicles are: heavy-load climbing is difficult, the climbing current is large, the speed is not fast, and the cruising range is not far enough. In response to the above problems, the new Datai six-phase permanent magnet synchronous (modular) control drive system developed by Datai Company has improved the reliability of the controller through the six-phase dual winding design of the motor and the modular controller shunt design. It has a large torque.

MORE >high

lights

Product Highlights

Energy efficient

Use modern design methods to reduce the power loss of the motor.

Powerful

With the same current, the climbing torque is doubled.

Long battery life

Small current and large torque can effectively reduce the impact of current on the battery.